Cutting wheel is a commonly used abrasive tool, widely used in metal, stone, ceramics and other materials cutting processing. Choosing a suitable manufacturer is crucial for obtaining high quality cutting wheels. How to choose a manufacturer? This article will cover the key factors and considerations for choosing a manufacturer to help you make an informed decision.

1. Product quality and certification

Quality control: Quality manufacturers pay attention to cutting wheel quality control. They adopt advanced production processes and strict quality management systems to ensure that every production link meets international standards and industry requirements. From the selection and inspection of raw materials, to the control of the production process and the testing of the product, all steps are carefully monitored to provide high-quality cutting wheels.

2, certification and standards

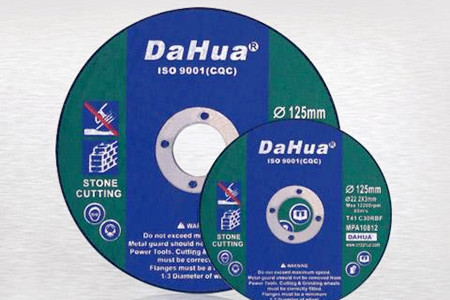

Quality manufacturers usually obtain the relevant certification and comply with international standards. For example, ISO 9001 quality management system certification and EN 12413 cutting and grinding tools safety standard. These certifications and standards are an important basis for measuring the quality and safety of manufacturers' products.

3. R&d capability and technical support

R&d team: It is very important to choose a manufacturer with a strong R&D team. This means that manufacturers have an advantage in new materials, new processes and product improvements. Through continuous research and development efforts, they are able to provide cutting wheels that meet market needs and industry trends.

Technical support: Quality manufacturers to provide comprehensive technical support and after-sales service. They have a professional technical team, can answer customers' technical questions in a timely manner, and provide technical advice, training and application suggestions. In addition, they are able to provide personalized solutions according to the special needs of customers.

4. Production capacity and supply capacity

Production capacity: Understanding the manufacturer's production capacity is an important consideration in the selection process. Consider the equipment level of the manufacturer, the size of the line and the level of technology to ensure that it can meet your needs. At the same time, understand its production cycle and delivery time, in order to make reasonable planning arrangements.

Supply capacity: Ensure that the manufacturer has a stable supply of raw materials and a mature supply chain management system to ensure the continuous supply of cutting wheels. Understand the manufacturer's inventory and supply capacity, so that the required cutting wheel can be replenished and deployed in time when needed.

5. Word of mouth and customer evaluation

Customer evaluation and word-of-mouth is an important reference for choosing manufacturers. Knowing what other customers say about a manufacturer's product quality, service, and responsiveness can help you better assess its reputation and reliability. Collect real feedback from customers through online reviews, reference cases, and customer referrals.

6. Price and cost performance

Price is one of the important factors in choosing a manufacturer, but it should not be the only decision-making factor. Make sure you understand the price level of different manufacturers and consider the cost performance of their product quality, technical support and service factors. Choose cost-effective manufacturers to obtain quality products and satisfactory purchasing experience.

The selection of high-quality cutting wheel manufacturers need to consider product quality, certification and standards, research and development capabilities, technical support, production capacity, supply capacity, reputation and customer evaluation as well as price and cost-effective factors. Ensure that the manufacturer has strict quality control and certification, has a strong R & D team and technical support, has a stable production and supply capacity, and has a good reputation and customer evaluation. By taking these factors into consideration, you will be able to choose a quality manufacturer that you can trust and work with.