When choosing a high-speed ultra-thin grinding wheel for different materials, a number of factors need to be considered. This product is a wide variety, according to the characteristics of different materials and processing needs, it is important to choose the right product.

1. Understand material properties

The hardness, density and structure of different materials vary, and it is necessary to understand their characteristics. For example, for metals with high hardness such as steel, rigid products with good cutting effect and wear resistance should be selected. For soft materials such as aluminum or copper, you can choose soft grinding wheels that do not cause excessive cutting.

2. Select the type of abrasive

Select the type of abrasive based on the workpiece material. Silicon carbide grinding wheel is suitable for hard materials such as metal, glass, ceramics, etc., while alumina grinding wheel is suitable for stainless steel, alloy steel, etc. Superhard abrasives such as diamond and boron nitride are suitable for processing high hardness and high strength materials.

3. Consider the product size

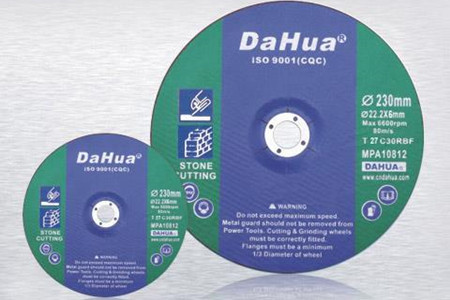

Select the appropriate size of the product to ensure that it matches the workpiece processing needs. Large size products are suitable for rough processing, small size is suitable for fine processing. Consider the product diameter, thickness, aperture and other factors to meet the processing requirements of specific workpieces.

4. Determine the grinding method and processing conditions

Different materials require different grinding methods. For hard materials, high-speed and high-pressure grinding methods can be used, while for soft materials, low-speed and low-pressure grinding methods should be selected to avoid damage to the workpiece surface.

5. Consider processing efficiency and surface quality

When selecting products, processing efficiency and desired surface quality need to be considered. Some products may be processed quickly, but will damage the surface quality of the workpiece; Other grinding wheels may be slower to process, but can provide higher surface accuracy.

6. Training and experience reference

When choosing a high-speed ultra-thin grinding wheel, you can consult a professional for their advice and experience. At the same time, continue to accumulate their own experience, through practical use and testing, to understand the performance of different products and scope of application.

7. Try and compare

For specific workpieces and processing needs, it is recommended to try and compare different brands and models of grinding wheels, and choose the one with good effect. Through the actual use of the test, find suitable for the job requirements of the product.

To sum up, the selection of high-speed ultra-thin grinding wheels suitable for different materials needs to fully consider the material characteristics, abrasive type, grinding wheel size, grinding mode and processing conditions, processing efficiency and surface quality, experience reference and trial comparison and other factors. Only according to the specific processing requirements, comprehensive consideration of these factors, in order to choose the appropriate products, improve processing efficiency and workpiece quality.