Grinding wheel is a common grinding tool, which is widely used in many industries and fields. Their materials are different, and different grinding wheels of different materials are suitable for different grinding tasks. The correct selection of materials can improve their working efficiency and service life.

1. What are the materials of this product?

1, carbonized silicon material: carbonized silicon material is a kind of high hardness, high durable grinding wheel, widely used in high-speed steel, cast iron, stainless steel and other materials grinding processing.

2, alumina material: alumina material products high hardness, wear resistance, suitable for steel, alloy, non-metal and other materials polishing, dressing and finishing.

3, diamond grinding wheel: diamond material product is a kind of high hardness, high strength, high rigidity grinding wheel, suitable for carbide, abrasive ceramics, high-speed steel and other materials precision grinding, cutting and surface dressing.

4, cubic boron nitride material: the product hardness and wear resistance of cubic boron nitride material are far more than other material products, suitable for cutting, meshing and dressing high hardness materials, such as carbide, quartz, ceramics and other materials processing.

2. How to select this product?

1, the selection of materials in line with the grinding object: when selecting the grinding wheel, we must first determine the characteristics of the grinding object, such as hardness, structure and geometric shape, and then select the material, abrasive particle, particle size, hardness, thickness and other suitable for the object of the grinding wheel.

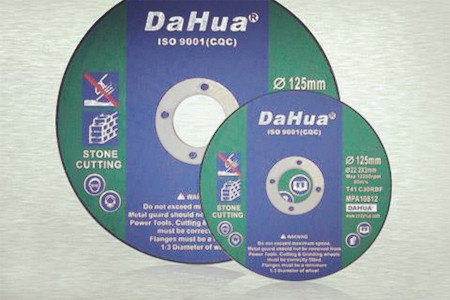

2, identify the grinding wheel logo: different materials of the product in the appearance of the difference, but the better way to identify is to see the logo. Identification usually includes information such as the shape, particle size, diameter and maximum operating speed of the product. If the mark is unclear or damaged, do not use it.

3, consider the processing requirements and process: not only the product material should match the grinding object, but also consider the processing requirements and process. Some special processing requirements and processes, such as high-speed processing, semi-dry grinding, one-time forming, etc., also affect the choice of products to a certain extent.

4, careful inspection when purchasing: When purchasing this product, you should carefully check the surface of the product, especially scratches, cracks and other damage. These damages can cause the grinding wheel to break or other safety hazards, so once such problems are found, the grinding wheel can no longer be used.

Select the appropriate grinding wheel material, reasonable use can improve the work efficiency and extend the service life of the product. When selecting, we should pay attention to four aspects: selecting materials to meet the grinding object, identifying the mark, considering the processing requirements and process, and carefully checking when purchasing. In order to obtain more efficient and safe results in grinding, the correct selection of materials is essential.