To be a world-class abrasive specialist Contact Us

| Production lines, material, color code Advanced manufacturing technology and special product formulas have permitted a high degree of product differentiation,enabling the user to select the most suitable reinforced cutting and grinding discs wheel for any specific application. | |

| Six material groups for reinforced cutting and grinding discs classification of material is based on their machining properties.The system of product label codes facilitates the choice of the optimum reinforced cutting and grinding discs. |

| Abrasive type code A | Grit size 30 | Hardness grade Q | Bond BF |

A= aluminum oxide C= silicon carbideZ= zirconia alumina grain ZA= zirconia alumina grain/Aluminum oxide AC=aluminum oxide/ silicon carbide WA= white corundum | 16-24=coarse 30-60=m 70-220=fine-medium | The hardness is graded from soft to hard by means of letters in alphabetically ascending order。 (A to Z) H-K= soft L-O= medium P-S= hard T-S= very hard | BF=Resinoid Bond Fibre=reinforced woven or ono-woven |

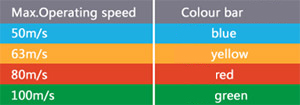

| Maximum operating speed | |

| The maximum operating speede(m/s)is shown on the product label and product packs by a color bar in accordance with the specification of EN12413.the maximum permissible R.M.P.specification applies to the nominal diameter of the tools. |

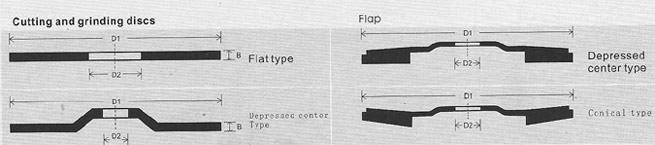

| Dimensions and shape |

| The diameter, thickness and center hole dimension are indicated in the drawings and tables by means of the following symbbols: |

| Safety Recommendations | |||

| Wear protective goeeles! |  | Wear protective gloves! |

| Wear ear protectors! |  | Wear dust respirator! |

| Observe safety recommendations! |  | Not approved for wet grinding! |

| Not approved for free-hand and hand-held operation! |  | Not approved for side grinding! |

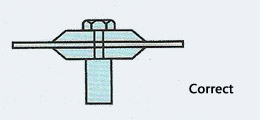

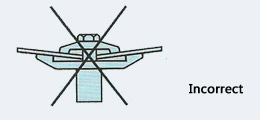

| Mounting system | |

| Never use flanges of different diameter Two flanges clamping a cutting and grinding tools must always have the same outside diametar and support area. | |

|  |